Rectifier units are our main product and specialization. Their main purpose is to convert supply network AC voltage into DC, with the voltage current in accordance with the technology requirements.

Rectifier units are manufactured with the parameters required for a specific production process. Modern components allow to manufacture units with current up to 150kA with DC voltage up to 2000V. If a higher current is required, a parallel connection of rectifier units is used, forming a DC substation.

| Rectifier unit current | kA | 2…150 |

| DC substation current | kA | Up to 500 |

| Rated DC voltage | V | Up to 2000 |

| Primary voltage of converter transformer

(AC grid voltage) |

kV | 0,4…220 |

| Valves | Diodes, thyristors | |

| Rectifier diagram | Graetz bridge

Two stars with interphase tarnsformer |

|

| Number of pulses | 6,12,24 | |

| Valves in parallel per rectifier leg | 1…12 | |

| Cooling | Air natural

Air forced Water Water-to-water Water-to-air |

The experience of specialists allows us to perform quality engineering and manufacturing of all rectifier elements, and a modern, fully digital control system guarantees high quality regulation, reliability and informative control.

Since rectifiers are usually made to meet individual requirements, you need to feel out a questionnaire to receive an offer.

EQUIPMENT LAYOUT

- Indoors, in the form of free-standing elements/cabinets.

- Indoors, in shelter (in the presence of adverse operating conditions)

- Outdoors in shelter (with cooling/heating).

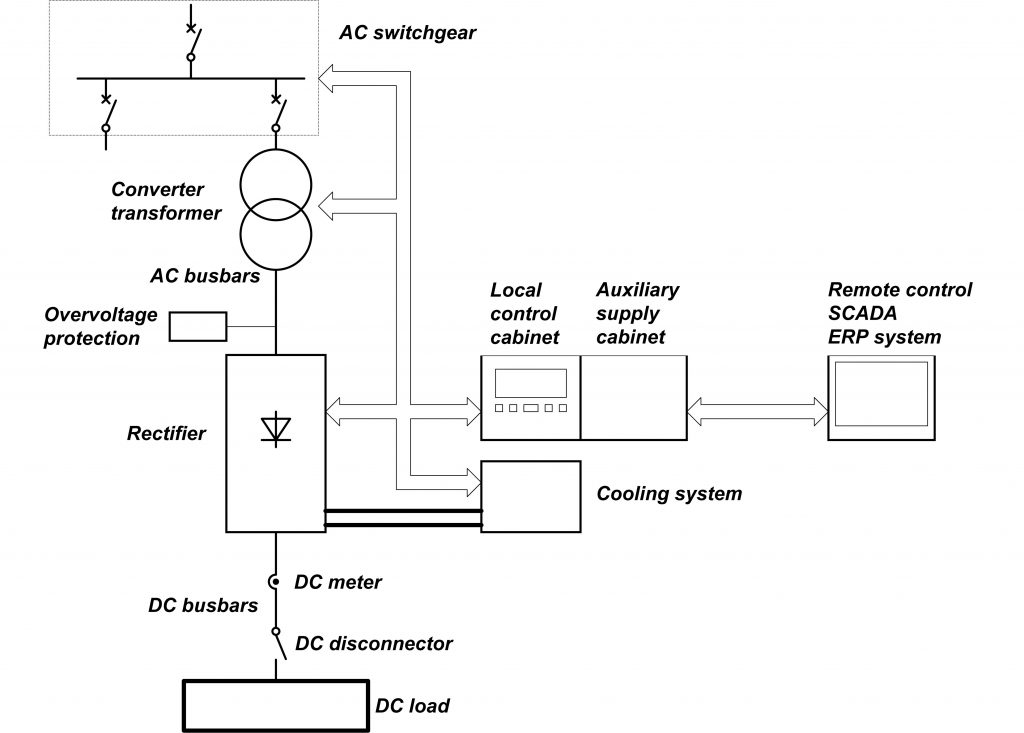

RECTIFIER UNIT MAIN PARTS

A generalized simplified diagram of the rectifier unit is shown below. Depending on the project, the entire set of equipment is supplied, as well as only components needed. Since most of the equipment is manufactured individually, please fill out a questionnaire to get a technical and commercial offer.

AC SWITCHGEAR

Delivery / Retrofit / Usage of existing equipment

Voltage fromот 0,4 up to 220kV, AIS or GIS.

CONVERTER TRANSFORMER

Specification / Delivery / Usage of existing equipment / Chief-erection /Chief-commissioning / Service

Primary voltage from 0,4 up to 220kV, secondary voltage – according rectifier and load parameters.

Oil-filled or dry-type, NLTC (no-load tape changer) or OLTC (on-load tape changer) of needed.

Oil-filled transformers are normally located outdoors, dry-type – indoors, near rectifier, or in shelter – together with the rectifier.

AC BUSBARS

Engineering / Components delivery / Chief-erection

OVERVOLTAGE PROTECTION

Engineering /Manufacturing/ Chief-erection / Commissioning/ Service

RECTIFIER

Engineering /Manufacturing/ Chief-erection / Commissioning / Service

Valves: diodes or thyristors

Diodes are used when the instantaneous value of DC does not need to be stabilized precisely. As a rule, diode units have a transformer with OLTC. Thyristor units are used when it is necessary to stabilize or precisely regulate the load current and have now displaced diodes from most applications.

COOLING SYSTEM

Engineering /Manufacturing/ Chief-erection / Commissioning / Service

- Air natural

- Air forced

Air-cooled systems are less efficient and are used for rectifiers with relatively low output current.

- Water-to-water

The rectifier is cooled by distilled water, which in turn is cooled by industrial water in a water-to-water plate heat exchanger.

- Water-to-air

The rectifier is liquid-cooled. The non-freezing deionized liquid itself is cooled by external air in a water-to-air heat exchanger.

AUXILIARY SUPPLY CABINET

Engineering /Manufacturing/ Chief-erection / Commissioning / Service

It is used for power supply of the unit’s own loads: pumps/fans of the cooling system, transformer control cabinets, local control cabinet of the unit, DC meters and other equipment of the unit. It has two independent inputs 0.4 kV with automatic standby activation.

LOCAL CONTROL CABINET

Engineering /Manufacturing / Chief-erection / Software development /Commissioning / Service

It is the central element of the control system. It contains main components: a PLC with a set of input/output and network exchange modules, a color graphic panel, indicator lights and control keys, galvanic isolation and thyristor control system boards (firing angle control system).

REMOTE CONTROL

Engineering /Manufacturing / Chief-erection / Software development /Commissioning / Service

Is used for remote control of the rectifier unit. In the simplest case, it is a cabinet with control keys, status lamps, an indicator of the current and voltage of the unit. In more complex systems, there is a graphical panel, a SCADA system, emergency control panel, bridge to enterprise management system.

DC busbars

Engineering / Components delivery / Chief-erection

DC meter

Specification / Delivery / Usage of existing equipment / Chief-erection /Chief-commissioning / Service

Depending on the project, DC shunts or fiber-optics current meters could be used.

DC disconnectors

Specification / Delivery / Usage of existing equipment / Chief-erection /Chief-commissioning / Service

They are used to disconnect the load from the rectifier unit (with no-load). Ritter or MERSEN disconnectors with main motor and secondary manual drives are used.