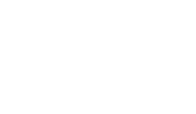

Thyristor rectifiers 63kA/450V

Year: 2015-2017

Process: magnesium electrolysis

Delivery: 6 pcs. local control cabinets for thyristor units (fully digital thyristor control with optic lines for control pulses), master control cabinet, substation operator SCADA control room, potline current optical sensor

Cooling: glycol/air

Semiconductors: thyristors

Scope (“turn-key”): full substation and equipment engineering, manufacturing, software development, erection and commissioning, power quality analysis and recommendations, local stuff training

Specifics: full replacement of existing unit/substation control system, keeping substation in operation.

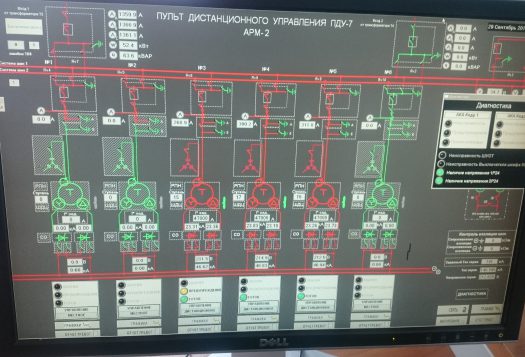

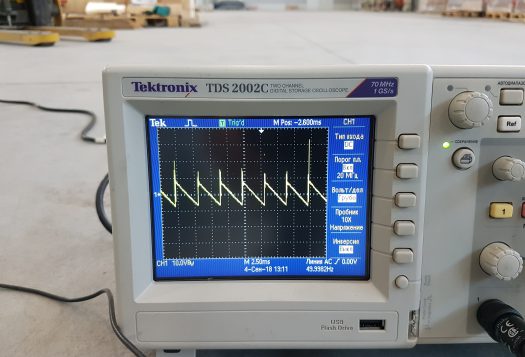

Thyristor rectifier units 28кА/60V

Year: 2016…2022

Process: VAR (titanium vacuum arc remelting)

Amount: 8 in operation/erection + 7 manufacturing/contracted

Cooling: water/water

Semiconductors: thyristors

Specifics: dry-type embedded transformer, shelter with aluminum walls IP54, auxiliary rectifier for arc stabilizing, each thyristor conductivity and reverse current sensor, fully digital thyristor control with optic lines, optical DC meter, complete factory testing witnessed by the end customer

Thyristor rectifier 25kA/60V

Year: 2019…2022

Process: VAR (titanium vacuum arc remelting)

Amount: 1+1

Cooling: water/water

Semiconductors: thyristors

Specifics: a specific design to meet existing busbar system and place available, auxiliary rectifier for arc stabilizing, each thyristor conductivity and reverse current monitoring, fully digital thyristor control with optic lines for control pulses, optical DC meter, complete factory testing witnessed by the end customer

Rectifier 6.3kA/450V

Year: 2015-2017

Process: nickel electrolysis

Equipment: Rectifier groups

Total amount: 20

Cooling: air direct

Specifics: replacement with new units with the same dimensions and Busbar arrangement

Rectifier 8kA/1000V + overvoltage protection cabinet

Year: 2017

Process: aluminum electrolysis

Total amount: 16

Cooling: air direct

Specifics: replacement with new units with the same dimensions