RETROFIT

At the moment, many industrial enterprises operate a large number of rectifier equipment manufactured in the 60-80 years of the last century. Its maintenance and repair are extremely difficult due to the fact that many of its elements cannot be repaired, and the components have been discontinued. At the same time, some elements are quite functional (AC/DC busbars, a converter transformer) and could still be operated. Also, installing of equipment with another dimensions dramatically increases the cost of civil works, and finally – the overall cost of the modernization project.

Depending on the actual condition of the equipment in operation and requirements currently imposed on it, different options are possible, the most common of which are the following:

CONTROL SYSTEM REPLACEMENT

It a good solution if existing equipment was produced no later than the end of the 80’s. The insulation is still in normal condition, relatively modern tablet-type thyristors are used. In this case, the power part remains practically unchanged, new thyristor pulse generators are installed in it to replace the existing ones, and if necessary, fuse status monitoring system or conductivity/reverse current sensors are installed. The control cabinet is completely replaced with a new microprocessor-based, new communication lines are laid, including optical patch-cords from control cabinet to the pulse generators in the power part. A full range of commissioning works is performed, including testing of protections and training of personnel.

Such works were performed on rectifiers 37.3kA of the Russian Copper Company. For 6 rectifiers 63kA of VSMPO-AVISMA [ссылка на соотвествующую страницу сайта] a complete control system replacement was done, despite all units were in operation less than for 10 years. The reason for the replacement was improper original design and low performance of the system, multiplied by the lack of support from the manufacturer.

In all these projects, we have undoubtedly managed to give these units a new life with low cost solution, dramatically increased their reliability and informative management.

RECTIFIER FEPLACEMENT

If the power equipment needs to be replaced as well, we can offer an excellent option – its replacement while maintaining the overall dimensions. New equipment is manufactured in full accordance with the overall drawing of the existing one. If no drawings of equipment installed exist, our engineer makes all measuring needed on site. Full compliance with the original dimensional drawing makes it possible to re-install rectifier in one day.

EXAMPLES OF PROJECTS COMPLETED

Rectifier Units 6.3kA/450V, 20 pcs.

BEFORE

AFTER

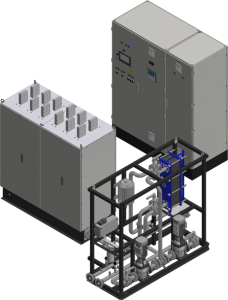

THYRISTOR RECTIFIER 25kA/60V

Remained: converter transformer, 6kV switchgear, AC/DC busbars

Replaced: rectifier, control system, cooling system, DC meter

Before

After